In the world of heavy industry, manufacturing, and large-scale maintenance, precision and power are not just goals; they are absolute necessities. The integrity of massive structures, the reliability of critical machinery, and the safety of personnel often depend on a single component: the fastener. Ensuring that every bolt and nut is tightened to the correct specification requires a specialized tool far beyond a standard spanner. This is the domain of the industrial torque wrench, a critical instrument designed to apply a specific, measured amount of rotational force, or torque, to a fastener, guaranteeing a secure and reliable connection every single time.

Essential for Power and Safety: The Torque Wrench for Heavy Machinery

When dealing with equipment in sectors like mining, construction, power generation, and aerospace, the scale is immense. The bolts used in a wind turbine or a large earth-moving vehicle can be several inches in diameter. The forces these connections must withstand are astronomical. For these applications, a specialized torque wrench for heavy machinery is not just recommended, it is mandatory. Using an inadequate tool can lead to under-tightening, where connections can vibrate loose, or over-tightening, which can stretch a bolt beyond its yield point, causing it to fail catastrophically under load. The consequences of such failures range from costly operational downtime to severe safety incidents. A proper torque wrench for heavy machinery, such as a hydraulic or large pneumatic model, provides the necessary leverage and controlled force to achieve the exact tension required, ensuring the structural and operational integrity of the equipment.

The Non-Negotiable Standard: Why a Calibrated Torque Wrench Matters

Possessing a powerful torque wrench is only half the battle; ensuring its accuracy is the other, equally important half. This is where calibration comes into play. A calibrated torque wrench is a tool that has been professionally tested and adjusted to ensure it performs within the manufacturer's stated accuracy limits. Over time, with repeated use, drops, and general wear and tear, any mechanical instrument can drift from its original settings. Using a tool that is out of calibration is a significant risk, as it provides a false sense of security. The technician may believe they are applying 1000 Newton-meters of torque, when in reality, the tool is only delivering 850 Nm. For any professional operation, relying on a calibrated torque wrench is a cornerstone of quality control and safety protocols. Regular calibration, often on an annual basis or after a specific number of cycles, is essential and should be documented to maintain compliance with industry standards like ISO 6789.

Decoding the Details: Understanding Industrial Torque Wrench Specifications

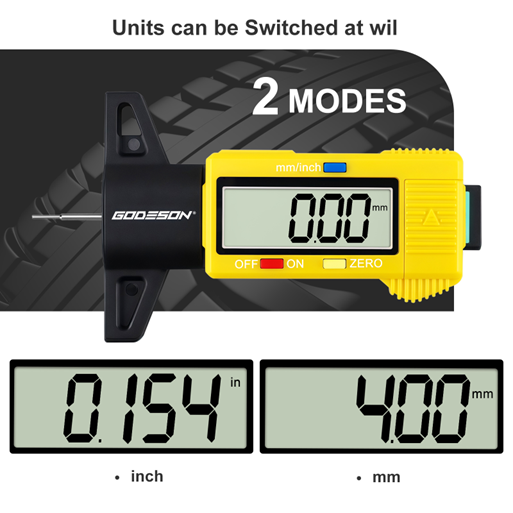

Selecting the right tool for the job requires a clear understanding of torque wrench specifications. These details determine the tool's suitability for a particular task and environment. The primary specification is the torque range, measured in Newton-meters (Nm) or foot-pounds (ft-lbs), which must encompass the requirements of the application. Another key factor is the drive size, typically ranging from 3/4" and 1" up to 2.5" for extreme applications, which dictates the size of sockets it can accommodate. Accuracy, usually expressed as a percentage (e.g., ±3%), is also critical; it defines the allowable deviation from the set torque value. Other important torque wrench specifications include the tool's length, which affects leverage; its weight and ergonomics, which impact user fatigue; and its mechanism type. Types range from mechanical click-wrenches that provide an audible signal, to digital models with precise LCD readouts, and powerful hydraulic systems for the highest torque demands. Carefully evaluating these specifications ensures the chosen industrial torque wrench is both effective and efficient for its intended use.

When Accuracy is Everything: The Role of a High Precision Torque Wrench

While all industrial applications demand accuracy, some environments require an even higher level of exactness. In fields like aerospace, automotive engine assembly, and medical device manufacturing, even the slightest deviation from the specified torque can compromise the final product's performance and safety. In these scenarios, a high precision torque wrench is indispensable. These instruments often boast accuracy ratings of ±1% or better and incorporate advanced technologies to eliminate user error. A high precision torque wrench is typically digital, offering features such as angle measurement for torque-to-yield-angle applications, programmable presets for repetitive tasks, and data logging capabilities. This ability to record the exact torque applied to each fastener provides an invaluable audit trail for quality assurance and compliance purposes. Investing in a high precision torque wrench is a direct investment in product quality, reliability, and risk mitigation in industries where there is no margin for error.