Torque Wrenches vs. Regular Wrenches: Key Differences

At first glance, torque wrenches and regular wrenches (like open-end or socket wrenches) look similar—but they serve very different purposes. Here’s how they compare:

|

Feature |

Torque Wrench |

Regular Wrench |

|

Primary Function |

Applies a specific, measurable amount of torque to fasteners. |

Applies force to turn fasteners (no torque measurement). |

|

Accuracy |

Designed for precision (most are accurate to ±2–4% of the set torque). |

Relies on guesswork or “feel”—easy to over/under-tighten. |

|

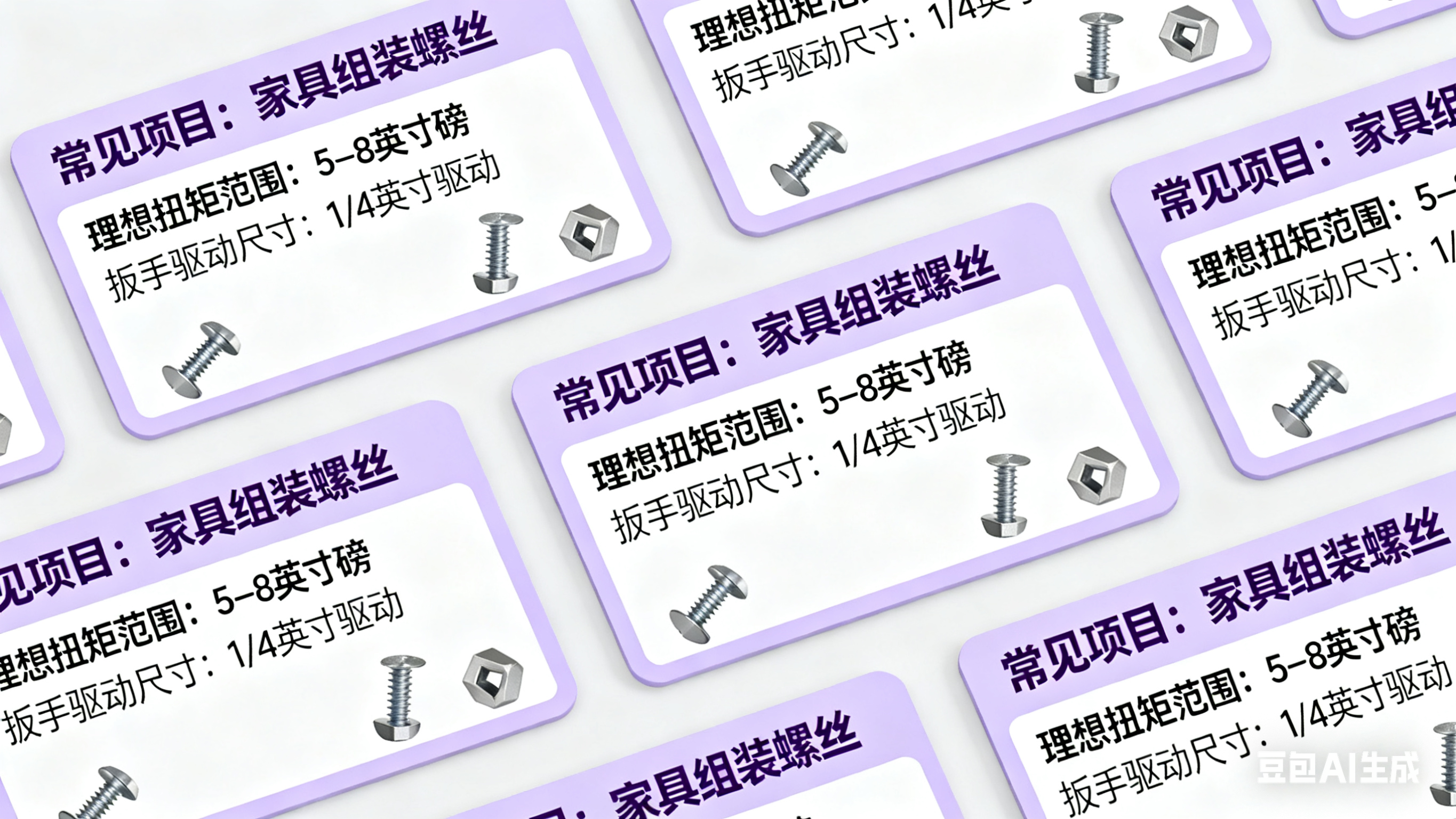

Use Cases |

Tasks where torque matters: automotive repairs (oil pans, wheels), bike assembly, machinery maintenance. |

Simple jobs: loosening stuck bolts, assembling non-critical furniture, basic plumbing. |

|

Design |

Has internal components (springs, sensors, or beams) to measure torque, plus a way to set/track values. |

Basic design: metal handle and head (no torque-related parts). |

|

Cost |

More expensive (budget models start at \(30; pro versions cost \)200+). |

Affordable (most cost $10–50). |

The bottom line: Regular wrenches work for quick, low-stakes tasks, but torque wrenches are non-negotiable when safety or part integrity is on the line. For example, using a regular wrench on car wheel lugs could lead to uneven torque—one lug too loose might cause the wheel to wobble, while one too tight could snap the bolt.