In the world of precision mechanics, from automotive repair to aerospace engineering, applying the correct amount of torque to a fastener is not just important—it's critical. For decades, mechanical click-type and beam wrenches were the standard, but technology has provided a superior solution for modern demands. The digital torque wrench has emerged as an indispensable tool, offering unparalleled accuracy, control, and user feedback that its analog predecessors simply cannot match. This evolution represents a significant leap forward in ensuring the safety, reliability, and longevity of assembled components.

Key Features of the Modern Electronic Torque Wrench

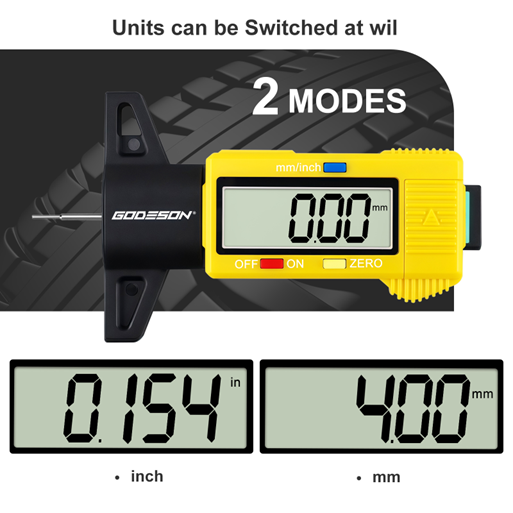

An electronic torque wrench, at its core, replaces mechanical springs and levers with sophisticated electronic strain gauges and a microprocessor. This fundamental difference unlocks a suite of features that enhance both functionality and ease of use. The most obvious feature is the digital LCD screen, which provides a clear, real-time readout of the torque being applied. This eliminates the guesswork associated with reading a dial or waiting for a physical click. Users can precisely set their target torque value, and the wrench provides progressive alerts as the target is approached. These alerts are often multi-sensory, including a sequence of flashing LED lights, an audible beeping that increases in frequency, and even a tactile vibration in the handle. This feedback system makes it nearly impossible to accidentally over-torque a fastener. Furthermore, these tools offer the ability to switch between multiple units of measurement (ft-lbs, in-lbs, Nm, kg-cm) on the fly, making them incredibly versatile for various projects and specifications. Many advanced models also include memory functions to store preset torque values and record the final torque applied for quality control and data logging purposes.

The Unmatched Value of a High Precision Torque Wrench

The primary reason to invest in a digital model is the need for exceptional accuracy. A high precision torque wrench is essential in applications where even a slight deviation from the specified torque can lead to catastrophic failure. Consider engine assembly, where head bolts must be tightened in a specific sequence and to an exact value to ensure a proper gasket seal and prevent warping. Or in the aerospace industry, where every fastener is critical to the structural integrity of an aircraft. Digital wrenches typically boast an accuracy of +/- 1% to 4%, a significant improvement over the +/- 4% to 6% or more found in many new mechanical wrenches, which can degrade further over time. This precision prevents common problems like stripped threads from over-tightening or components loosening under vibration from under-tightening. The consistent and repeatable performance of a digital wrench ensures that every bolt is tightened to the same specification, every single time, which is a cornerstone of quality manufacturing and repair work.

Maintaining Accuracy Through Electronic Torque Calibration

Like any precision instrument, a digital torque wrench requires periodic maintenance to ensure its accuracy remains within specifications. This process is known as electronic torque calibration. Over time and with repeated use, the electronic sensors can drift, leading to inaccurate readings. Calibration involves comparing the wrench's output to a highly accurate torque sensor that is itself traceable to national or international standards. If a deviation is found, the wrench's internal software is adjusted to bring it back into perfect alignment. Most manufacturers recommend a calibration interval of once a year or every 5,000 cycles, whichever comes first. Ignoring calibration can negate the primary benefit of owning a precision tool, as an inaccurate wrench can provide a false sense of security while leading to improper fastening. Professional calibration services provide a certificate documenting the tool's accuracy, which is often a requirement for professional shops and industrial quality control systems.

How to Choose the Best Digital Torque Wrench

Selecting the best digital torque wrench depends entirely on your specific needs. The first factor to consider is the torque range. A wrench designed for small engine or bicycle repair will not be suitable for working on truck suspension, and vice versa. It's best to choose a wrench where your most commonly used torque values fall in the middle 20-80% of its total range for maximum accuracy. Next, consider the drive size (1/4”, 3/8”, 1/2”, etc.), which should match the sockets you use most frequently. Look at the tool's stated accuracy and ensure it meets the requirements of your work. Build quality is also paramount; a sturdy metal body and a comfortable, non-slip grip are signs of a durable tool. Finally, evaluate the feature set. Do you need peak/track modes, which show either the highest torque applied or a live reading? Is data storage and USB output important for your work? By carefully considering these factors, you can find a tool that is a perfect fit for your workshop and will serve as a reliable instrument for years to come.