The Different Types of Torque Wrenches: Which One Fits Your Project?

Not all torque wrenches are the same—each type is built for specific tasks, so choosing the right one ensures accuracy and ease of use. Let’s break down the most common options:

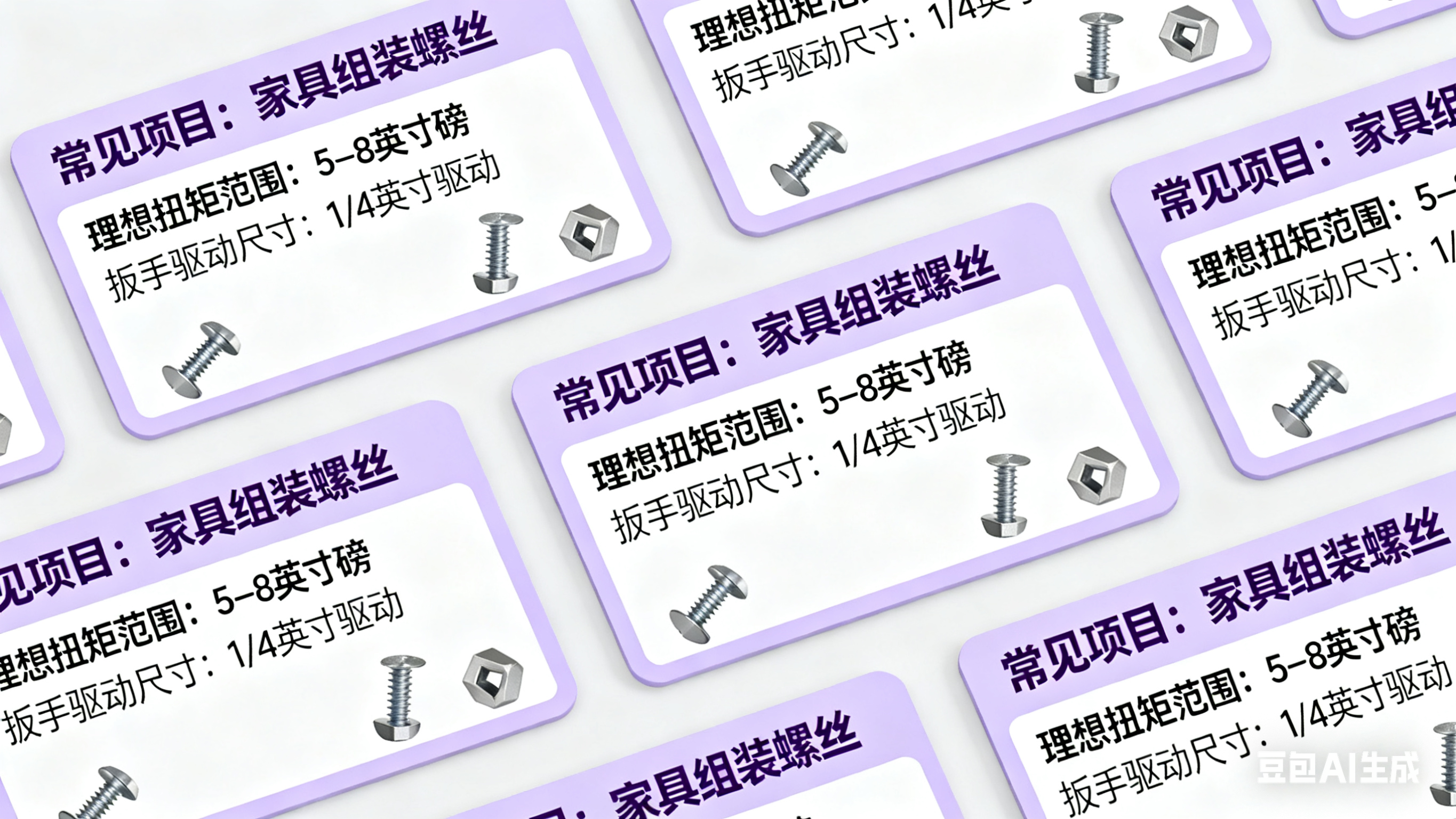

1. Click-Type Torque Wrench: The most popular choice for DIYers and professionals alike. It lets you set a torque value, then emits a “click” when you’ve reached it (you’ll also feel a slight give). It’s durable, affordable, and works for most projects—from automotive repairs to furniture assembly.

1. Beam-Type Torque Wrench: A simple, budget-friendly option with a straight beam and a needle that moves as you apply force. The needle points to the current torque value on a scale. It has no moving parts (other than the needle), so it’s low-maintenance—but it’s less precise for small torque values and requires you to keep the wrench level to read accurately.

1. Digital Torque Wrench: High-tech and easy to read, with an LCD screen that displays torque in real time. Many models beep or flash when you hit the set value, and some store torque data for later. They’re great for precision tasks (like electronics or aerospace work) but cost more and need batteries.

Hydraulic Torque Wrench: Used for heavy-duty industrial jobs (e.g., construction or large machinery). It uses hydraulic pressure to deliver extremely high torque, making it unsuitable for home use.